Blade technology designed and developed for high-precision slicing and dicing.

Our blade technologies are designed for precision slicing and dicing of soft to hard materials of many different types and elements that are used in hard disk drive, optical and semiconductor applications. Blades are produced with state-of-the-art manufacturing techniques to ensure tightly-controlled dimensional and thickness tolerances are maintained.

ELECTROFORMED BOND HUBLESS BLADE

Advanced electroformed manufacturing process capable of producing ultra-thin blades with high strength and stiffness characteristics. Blades keep their shape and provide longer life.

Please inquire for more details.

- Wide selection of blade options

- Proprietary thin-blade technology

- Bond customization options

- Blade thickness down to 25µm available

- Ceramics

- Magnetic materials

- PCB

- Silicon

METAL BOND HUBLESS BLADE

Formulated sintered metal bond matrix designed to hold and retain diamond grains to increase blade longevity. Blades have a lower wear resistance when compared to standard formulations and help reduce defects such as slanted-kerf

Please inquire for more details.

- Wide selection of blade options

- Special metal bond matrix formulation

- Excellent rigidity and cut quality

- Blade thickness down to 45µm available

- BGA

- CSP

- Optical

- Sapphire

RESIN BOND HUBLESS BLADE

Resin bond matrix developed to reduce the occurence of diamond grain deformation and aid in new diamond exposure. Blades provide good cutting efficiency and quality on hard and brittle materials.

Please inquire for more details.

- Wide selection of blade options

- Bond matrix allows for high speed processing

- Improved cut quality on hard materials

- Blade thickness down to 50µm available

- Hard and brittle materials

- IR filter

- Optical

- WFN

- Splitter

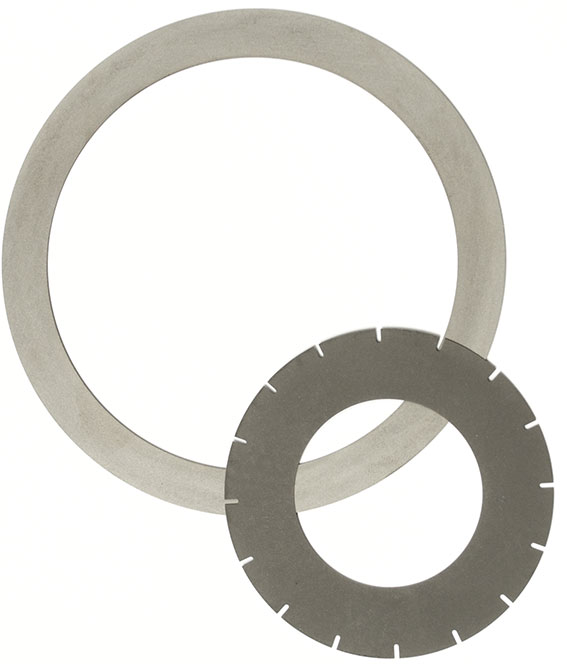

VITRIFIED BOND HUBLESS BLADE

Vitrified bond developed with high rigidity to enhance the straightness of the entry cut and to provide precise cutting during high-loading applications. Blades work well on hard materials, such as crystals and sapphires.

Please inquire for more details.

- Wide selection of blade options

- Excellent for high-loading and hard materials

- Enhanced straight cutting capability

- Blade thickness down to 70µm available

- Ceramic

- Crystals

- Sapphire