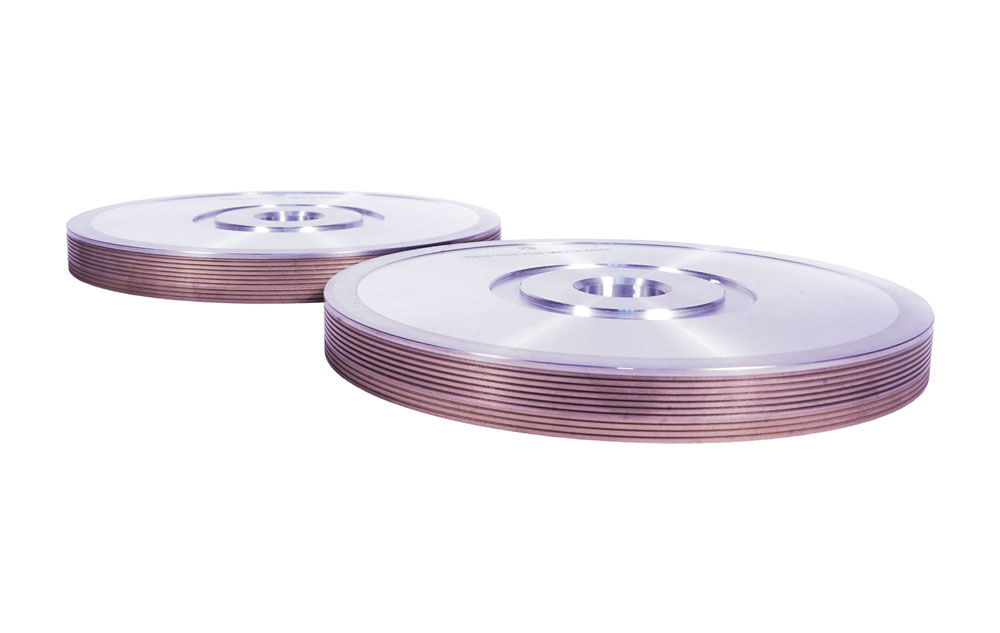

Manufactured with tightly distributed fine grade synthetic diamond particles for consistent wafer-to-wafer edge grind process.

Wheels can be tailored to your desired groove dimensions and adjusted to a grit size of up to 3,000 for fine grind applications.

Each groove of the wheel is precisely machined by our EDM (electrical discharge machining) process for strict geometric tolerance control. Up to 10 grooves and 2 grit types (rough and fine) can be included into any one wheel. Fine adjustments in hardness and other diamond bond characteristics can be modified for optimization to the end process.

ADVANTAGES

- Improved surface roughness

- Increased lifetimes

- Tightly controlled diamond distribution

- Uniform bond structure

- Highly accurate EDM processing

- Improved wafer-to-wafer consistency

COMMON APPLICATIONS

- Ceramics

- Gallium Arsenide

- Gallium Nitride

- Glass

- Germanium

- Sapphire

- Silicon

- Silicon Carbide

PRODUCT AVAILABILITY

GRIND APPLICATIONS

Rough and Fine

WHEEL DIAMETER (mm)

102 or 202

BOND TYPE (mm)

Metal (Standard or Hard)

GRIT TYPE

Synthetic Diamond

GRIT (JIS)

400 to 3,000

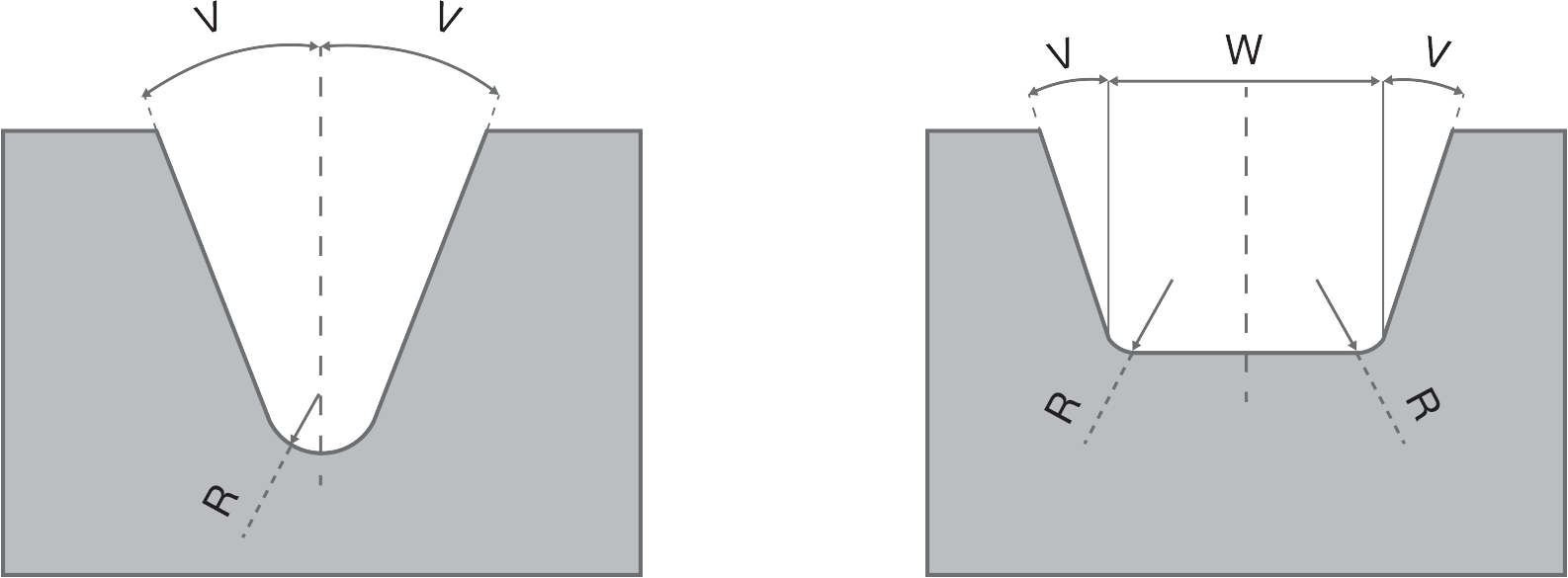

GROOVE TYPE

V, R or Custom

GROOVE PROFILES

COMMON TOOL CONFIGURATIONS

- DAITRON®

- TOSEI®

Have questions regarding our edge grind wheels or interested in a custom product? Please contact us for additional information!