Industry leader in Semiconductor grade PVA sponge products.

For over 60 years AION has been the leading supplier of polyvinyl alcohol (PVA) sponge products to the semiconductor, hard disk and LCD markets. This experience coupled with a relentless drive to improve our products, allows us to offer PVA brushes with superior cleanliness. Our metal, anion and particle levels are of the best in the industry.

PVA BRUSH ROLLERS

AION PVA brushes have been developed to meet the requirements of today’s most critical cleaning applications for a wide range of highly technical markets. Our products are designed with proprietary manufacturing and special clean processes to match application requirements.

For Post-CMP cleaning processes, our advanced PVA brushes have been formulated to be compatible with the cleaning chemistries used in 250nm to 32nm and below technologies and low-k materials.

ADVANTAGES

- Improved brush break-in times

- Increased product yield performance

- Higher cleaning efficiencies

- Best-in-class particle levels

- Specially designed flow-thru cores

- Proprietary formulations for sub 14nm

COMMON APPLICATIONS

- Semiconductor grade wafers

- Hard disk substrates (Glass and Al)

- Optical wafers

- Post-CMP applications

Prior to Shipping our advanced brush products, a 100% visual inspection and check is completed to ensure proper adherance to our strict quality control standards. Thereafter, products are specially packaged to prevent contamination and bacteria growth during transport and storage.

COMMON TOOL SETS

HARD DISK DRIVE

| EQUIPMENT | XYRATEX® |

|---|---|

| Al/Glass | OLIVER® |

| Al/Glass | TWIN RAIL® |

SEMICONDUCTOR

| EQUIPMENT | APPLIED MATERIALS® | EBARA® | LAM/ONTRAK® | SPEEDFAM/IPEC® |

|---|---|---|---|---|

| 200mm | MIRRA MESA® | EPO/F*REX® | DSS/SYNERGY/INTEGRA® | CLARUS/7700/AURIGA-C® |

| 300mm | REFLEXION® | F*REX300S/X® |

Have questions or interested in our Brush Rollers? Contact us below!

FLAT BRUSH ROLLERS

AION PVA flat rollers have unique material properties that make them suitable for applications that require the control of liquids by absorption or for coating processes. The elastic and uniform characteristics of our formulation of our sponge roller helps to evenly distribute coatings consistently, from roller to roller.

ADVANTAGES

- Exceptional liquid control

- Excellent water absorption

- Good mechanical and chemical resistence

- Rigorous quality control checks

- Available with/without PVC core

COMMON APPLICATIONS

- Cleaning of glass components

- Printed circuit boards

- Lead frames

- Coating of water-soluble adhesives

- Coating of anti-static agents

- Coating of paints

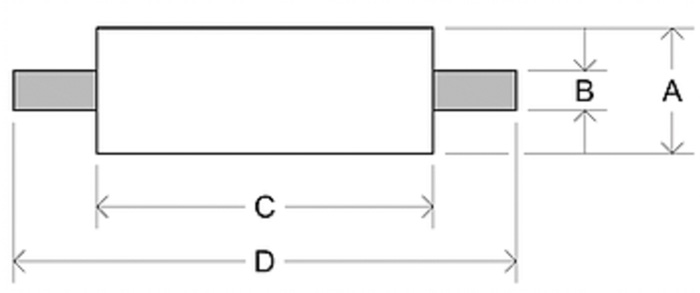

STANDARD DIMENSIONS

STANDARD PROPERTIES

| A - Outer Diameter (mm) | B - Inner Diameter (mm) | C - Length (mm) | D - Legnth of Core (mm) |

|---|---|---|---|

| 40 | 20 (16) | 500 ~ 600 | Sponge Length (C) +60 ~ 100 |

| 50 | 26 (20) | 500 ~ 600 | |

| 60 | 26 (20) | 500 ~ 800 | |

| 67 | 26 (20) or 32 (25) | 500 ~ 800 | |

| 77 | 32 (25), 38 (31) or 48 (40) | 500 ~ 1,000 | |

| 100 | 48 (40) or 60 (51) | 500 ~ 1,200 | |

| 125 | 76 (67) or 89 (77) | 500 ~ 1,500 | |

| 194 | 89 (77) | 500 ~ 2,000 | |

| 240 | 165 (146) | 500 ~ 2,000 |

Have questions or interested in our Flat Rollers? Contact us below!

PVA CLEANROOM SPONGES

AION PVA sponges are used for absorbing and wiping critical and delicate surfaces. Our PVA’s highly absorbent, water retention and abrasive resistent properties make it suitable for many types of manual cleaning applications. Unlike paper or fibrous material wipers, no lint or waste is generated during use. In addition, the micropores and hydrophilic characteristics of our material help to remove small particulates and absorb water effectively.

ADVANTAGES

- Continuous open pore structure

- Various pore sizes and porosities

- Super absorbent for high liquid rentention

- Resilient material properties

- No lint or waste generation

COMMON APPLICATIONS

- Wiping and water absorbtion

- Electronics

- Optics

- Pharmaceutical apparatus

- Manufacturing equipment

- Workbenches

| TYPE | E-1 | E-2 | D-1 | D-2 | D-3 |

|---|---|---|---|---|---|

| SIZE (mm) | 230 x 230 x 1 | 230 x 230 x 2 | 230 x 230 x 1 | 230 x 230 x 2 | 125 x 85 x 35 |

| STATE (DRY/WET) | DRY | DRY | DRY | DRY | WET |

| PORE DIAMETER ('m) | 130 | 130 | 80 | 80 | 80 |

| POROSITY (%) | 90 | 90 | 89 | 89 | 89 |

| HEAT RESISTANCE ('C) | 60 or below | 60 or below | 60 or below | 60 or below | 60 or below |

Have questions or interested in our Cleanroom Sponges? Contact us below!