Ultra-Precision Carrier Manufacturing

for double-sided polishing and lapping.

Our carriers yield the reliability and precision performance demanded by our customers.

We are proud to offer materials that meet the stringent thickness tolerances required in our industry (+/- 0.0001′]). Our sophisticated and proprietary manufacturing processes transform high quality sheet materials into state-of-the-art carriers. Our overall system flexibility provides customers with highly customized products and services to support their rapidly changing manufacturing environment.

STANDARD MATERIALS

- G-10/FR-4u Glass reinforced epoxy laminate

- Steel Metal Alloy

- Steel with Insert Metal Alloy with Polymer or Laminate Insert

- PVC Vinyl Thermoplastic Polymer

STANDARD TOOL CONFIGURATIONS

- HAMAI®

- PETER WOLTERS®

- SPEEDFAM®

- SYSTEM SEIKO®

- TAIYO®

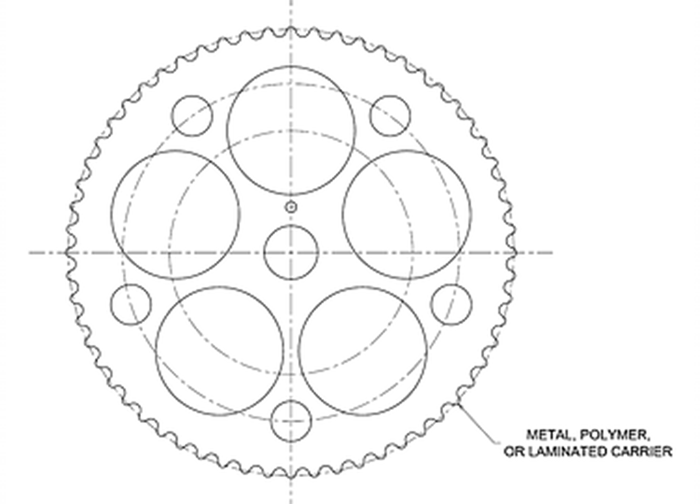

CUSTOMIZED DESIGN

To help us get started, please use the below carrier drawing form to submit any new carrier design requests or changes.

CUSTOMIZABLE OPTIONS

- Teeth Dimensions

- Pocket Dimensions

- Number of Pockets

- Carrier Thickness

- Slurry Hole Dimensions

INSERT CARRIERS

We specialize in the precision manufacturing of insert carriers used for double-sided lapping and polishing processes. Our insert carriers are made with special techniques that allow for different types of polymers or laminate materials to be used as the edge insert. Techniques also include injection molding inserts directly onto the stainless-steel base with a proprietary process that prevents de-lamination of the edge insert.

ADVANTAGES

MATERIAL OPTIONS

- Glass Laminate

- Kevlar Laminate

- Nylon

- POM (Acetal)

STANDARD INSERT CARRIER THICKNESSES (mm)*

- 0.30 0.70

- 0.40 0.80

- 0.50 0.90

- 0.60 1.00

To help us get started, please use the below carrier drawing form to submit any new carrier design requests or changes.